Parameters

| Main technical parameters |

Rated capacity

(kVA) |

Connect

groups | Voltage combination(KV) |

No-load loss W |

Load loss W |

No-loadcurrent(%) |

Short-circuit

impedance(%) |

voltage |

Tapping range | Low

voltage |

| 630 | Yd11 | 35 | ±5% | 3.15

6.3

10.5 | 830 | 7870 | 1.10 | 6.5 |

| 800 | 980 | 9410 | 1.00 |

| 1000 | 1150 | 11540 | 1.00 |

| 1250 | 1410 | 13940 | 0.90 |

| 1600 | 1700 | 16670 | 0.80 |

| 2000 | 2180 | 18380 | 0.70 |

| 2500 | 2560 | 19670 | 0.60 |

| 3150 | 35~38.5 | ±5% | 3.15

6.3

10.5 | 3040 | 23090 | 0.56 | 7.0 |

| 4000 | 3620 | 27360 | 0.56 |

| 5000 | 4320 | 31380 | 0.48 |

| 6300 | 5250 | 35060 | 0.48 | 7.5 |

| 8000 | Ynd11 | 35~38.5 | ±5%

或

±2×2.5% | 3.15

3.3

6.3

6.6

10.5

11 | 7200 | 38500 | 0.42 |

| 10000 | 8700 | 45300 | 0.42 |

| 12500 | 10080 | 53900 | 0.40 | 8.0 |

| 16000 | 12160 | 65800 | 0.40 |

| 20000 | 14400 | 79500 | 0.40 |

| 25000 | 17020 | 94100 | 0.32 |

| 31500 | 20220 | 112900 | 0.32 |

Note 1: For transformers with a rated capacity of 6300kVA and below, products with a high-voltage tapping range of±2×2.5%can be provided.

Note 2: For transformers with low-voltage voltages of 10.5kV and 11kV, products with connection group number Dyn11 can be provided.

Note 3: For transformers with a rated capacity of 3150kVA and above,the-5%tap position is the maximum current tap.

| Three-phase double-wound on-load voltage regulating power transformer with a capacity of 2000kVA to 20,000kVA |

Rated capacity

(kVA) |

Connect

groups | Voltage

combination(kV) |

No-load loss W |

Load loss W |

No-load

current(%) |

Short-circuit

impedance(%) |

High

voltage |

Tapping range | Low

voltage |

| 2000 | Yd11 | 35 | ±3×2.5% | 6.3

10.5 | 2300 | 19240 | 0.80 | 6.5 |

| 2500 | 2720 | 20640 | 0.80 |

| 3150 | 35~38.5 | ±3×2.5% | 6.3

10.5 | 3230 | 24710 | 0.72 | 7.0 |

| 4000 | 3870 | 29160 | 0.72 |

| 5000 | 4640 | 34200 | 0.68 |

| 6300 | 5630 | 36800 | 0.68 | 7.5 |

| 8000 | Ynd11 | 35~38.5 | ±3×2.5% | 6.3

6.6

10.5

11 | 7870 | 40600 | 0.60 |

| 10000 | 9280 | 48100 | 0.60 |

| 12500 | 10940 | 56900 | 0.56 | 8.0 |

| 16000 | 13170 | 70300 | 0.54 |

| 20000 | 15570 | 82800 | 0.54 |

Note 1: Fortransformers with low-voltage voltages of 10.5kV and 11kV, products with connection group number Dyn11 can be provided.

Note 2: The maximum current tap is at the-7.5%tap position.

When the number of tap stages and the stage voltage remain unchanged, it is allowed to increase the number of negative tap stages and decrease the number of positive tap stages, or increase the number of positive tap stages and decrease the number of negative tap stages, such as(353)×22.5%.

Use

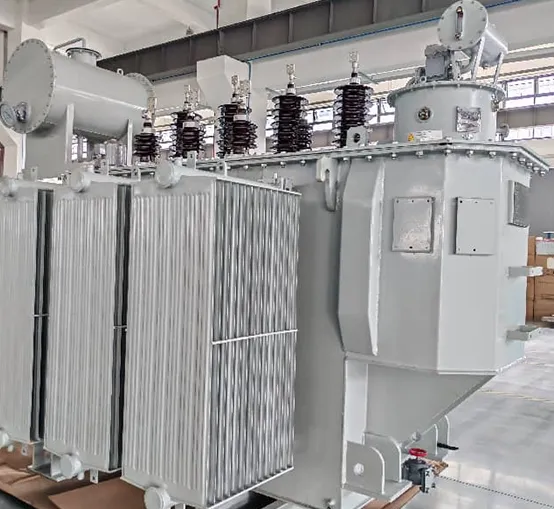

Based on 35 kva transformert's high reliability, low loss, strong short-circuit resistance, and efficient heat dissipation, this oil-immersed power transformer is mainly suitable for power system scenarios that have high requirements for power supply stability, energy efficiency, and equipment durability. Specifically, 35 kva transformer can be applied in:

Power transmission and distribution: As the main transformer in regional power grids, 35kv distribution transformer is used for voltage reduction or increase at the 35kV voltage level, connecting power grids of different voltage levels, and ensuring power transmission in urban power grids, industrial park power grids, etc.

Industrial and infrastructure: 35 kva transformer is suitable for large industrial plants (such as manufacturing factories, heavy industrial bases), industrial parks, and other scenarios that require a stable, high-power supply. 35 kva transformer can also be used in infrastructure power systems with high requirements for equipment reliability (such as power grids for large transportation hubs, power supply systems for key public buildings, etc.).

Other specialized power scenarios: 35 kva transformer is suitable for power projects that have clear requirements for transformer impact resistance and low loss, especially for power nodes that need long-term stable operation and reduced maintenance intervention.

English

English