Benefits

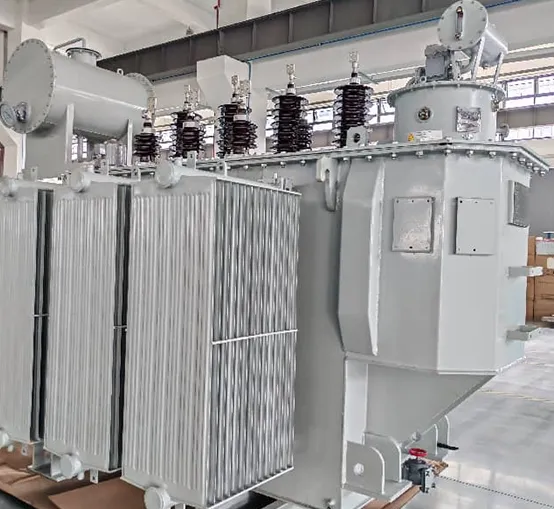

Modularization -Intelligent prefabricated cabins play a crucial role in the power system. In the process of power transmission and distribution, electricity, the changes in voltage and current can cause certain impact and interference to electrical equipment. If the equipment is not properly protected, it is easy to cause problems Malfunction or damage. As a closed device, prefabricated cabins can provide a relatively stable working environment for electrical equipment, reduce external interference, and improve the reliability and stability of the equipment.

In addition, modular intelligent prefabricated cabins also have good flexibility and scalability. Due to the modular design of prefabricated cabins. A prefabricated cabin can be combined and expanded according to actual needs, so e house can be customized according to the scale and development needs of the power system. At that time, the electrical e house equipment inside the prefabricated cabin can also be upgraded and replaced as needed to adapt to the constantly changing demands of the power system.

In addition to the advantages mentioned above, modular intelligent prefabricated cabins also have some other features. For example, an electrical e houseadopts advanced technology. The control technology enables remote monitoring and control, improving the automation level of the power system. In addition, prefabricated cabins also have good. Good ventilation and heat dissipation performance ensure that the equipment will not be damaged due to overheating during long-term operation. At the same time, prefabricated cabins also have a certain. Seismic performance is able to maintain the stable operation of equipment during natural disasters such as earthquakes.

In practical applications, modular intelligent prefabricated cabins are widely used in various power systems, including power plants and substations. Distribution network, etc. In these application scenarios, prefabricated cabins not only provide a good working environment for electrical equipment but also improve the power system. The overall operational efficiency and stability. Meanwhile, due to the modular and scalable nature of prefabricated cabins, they can also be customized according to different requirements and expanded to meet the constantly evolving needs of the power system.

Use

Modularization-Intelligent prefabricated cabin is an important piece of equipment in the power system and is an indispensable device in the power system. A prefabricated cabin has multiple advantages, such as protecting electrical equipment, improving the stability and reliability of power systems, and achieving remote monitoring and control, and is widely used in various power systems. With the continuous development and upgrading of the power system, prefabricated cabins will continue to play an important role in providing strong support for the stable operation of the power system. Mainly used for control and protection in the process of power transmission and distribution. The prefabricated cabin function is to provide a safe and reliable environment to protect electrical equipment and components from external environmental influences, ensuring the stable operation of the power system.

Modularization-Compared with traditional power stations, intelligent prefabricated cabins require a large amount of civil engineering work, on-site installation and commissioning of internal equipment, and high costs. And modularization of main power distribution equipment, heating, cooling, ventilation, lighting, fire alarm, monitoring, and other supporting equipment inside the intelligent prefabricated cabin are assembled and debugged in the factory, greatly shortening the on-site construction period and saving a lot of manpower and material resources. At the same time, prefabricated cabin has many advantages, such as small radiation, low cost, small footprint, short production cycle, and small on-site construction volume.

English

English