en

-

Products

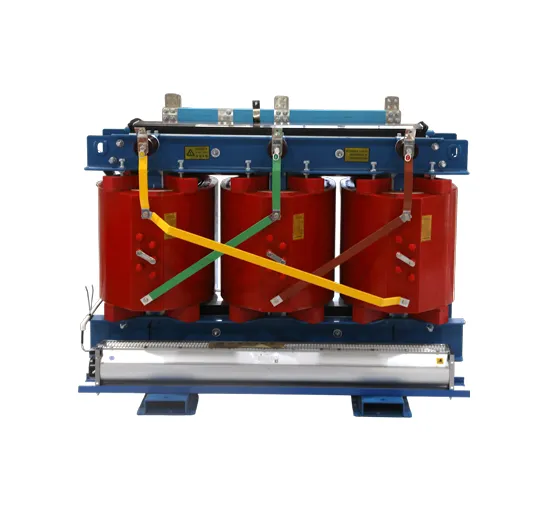

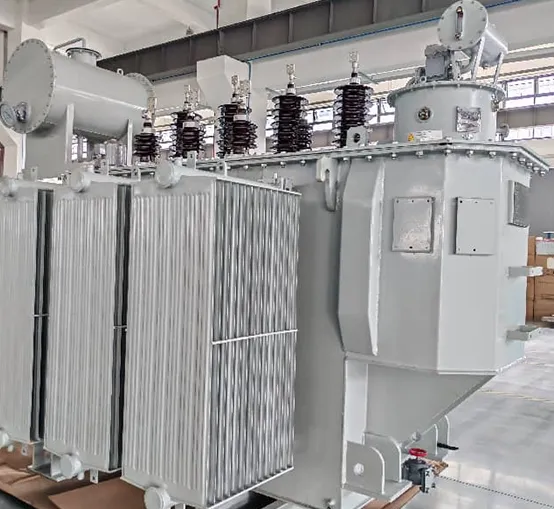

SZ13-MT 11KV On-load Capacity and Voltage Regulation Fully Sealed Oil-immersed Distribution Transformer 6KV-11KV Oil Immersed Distribution Transformer Three Phase Oil Immersed Distribution Transformer Medium Voltage High Voltage Power Distribution Transformer 11KV Oil-immersed Power Transformer 11KV S11 Oil-immersed Power Transformer Single Phase Ground Mounted Transformer Single Phase Pole Mounted TransformerSCB14 (Nx1) Series Dry-type Power Transformer SCB18 (Nx1) series dry-type power transformer 6KV-11KV Three Phase Dry Type Distribution Transformer Epoxy Resin Dry-Type Transformer Three Phase Dry-Type Transformer35KV High-Voltage Power Transformer 35kV High-Voltage On-Load Tap-Changing Highland Power Transformer35kV Mining Skid-Mounted Outdoor Substation E-House prefabricated Electrical Cabin Box-type Transformer Substation European Style Pad-Mounted Transformer Substation American Style Photovoltaic Substation、Wind-Power Substation High-Voltage & Low-Voltage Prefabricated Substation

- Solutions

- News

- Resources

- About Us

- Contact Us

English

English