A

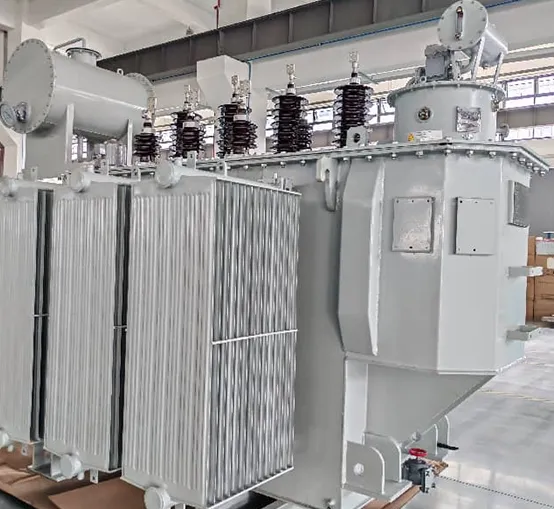

Core: Made from silicon steel laminated to minimize energy loss.

Primary Winding: Receives power from the input.

Secondary Winding: Provides output power.

Insulation: Helps prevent short circuits.

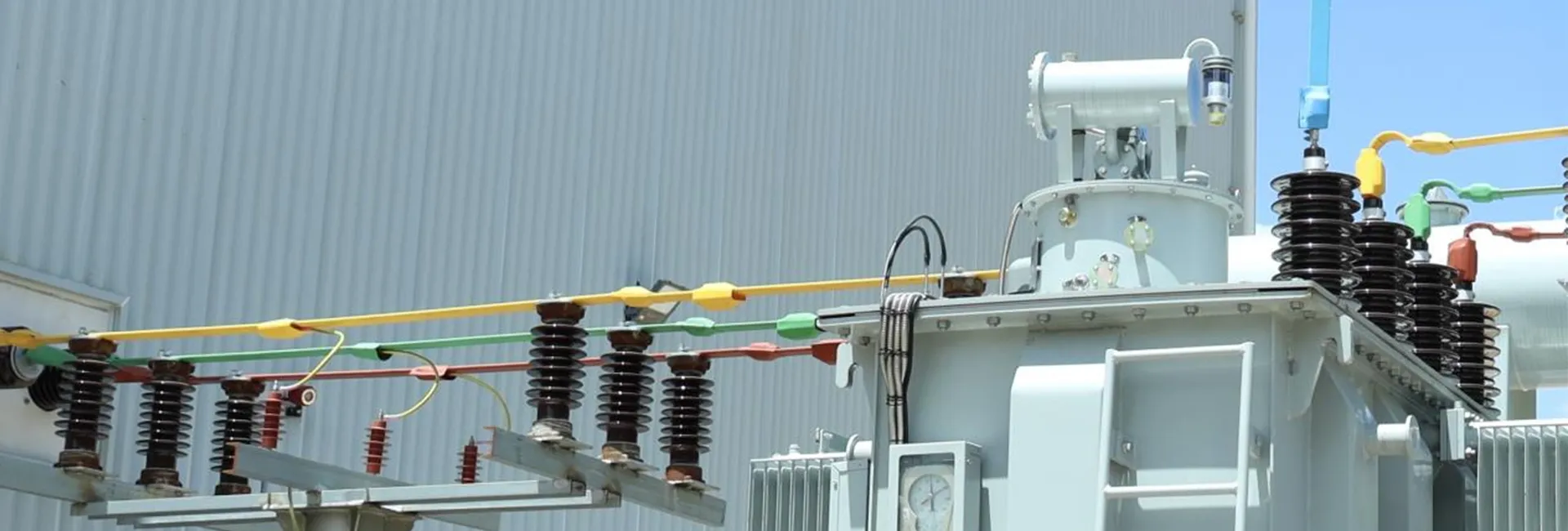

Tank: Guards internal components. It is typically filled with cooling oil.

Types of Single-Phase Transformers

A Step-Up Transformer is a transformer that increases the voltage from the primary side to the second side.

Step-Down Transformer: Lowers voltage from the primary side to the Secondary side.

Isolation Transformer: Provides electrical isolation while maintaining the same voltage.

Applications of Single-Phase Transformers

Residential Power Supply: Designed to supply power to homeowners.

Lighting Systems: Provides lighting in public and private spaces.

HVAC Systems: Powers heating and ventilation systems as well as air conditioning systems.

Small industrial equipment: Delivers electricity to machines that have less voltage specifications.

Electronic Devices: Assures a steady power supply for computers and home appliances.

Advantages of Single-Phase Transformers

Cost-effective: Less expensive than three-phase transformers designed for applications with low power.

Small Size: Suitable for installations that have limited space.

Simple Installation: A simple set-up process can reduce the time needed for installation.

Low Maintenance: It requires minimum maintenance throughout its life.

Efficient for small Loads: Ideal for moderate to low power demands.

Disadvantages of Single-Phase Transformers

Limited Power Capacity This product is not suitable for heavy industrial applications.

Voltage Fluctuations:More susceptible to voltage drops than three-phase systems.

· Higher Losses:You may be more susceptible to losses in the transmission of power over long distances.

Why Choose Makpower Transformers in West Bengal?

Makpower Transformers is a trusted manufacturer located in West Bengal that specializes in quality single-phase transformers. With years of experience in the field, Makpower offers reliable and efficient transformers that are designed to meet the requirements of commercial, residential, and light industrial customers. Our products are tested rigorously to ensure durability, safety, and efficiency.

Key Features of Makpower Single-Phase Transformers

High Efficiency: Reduces energy losses, ensuring optimal performance.

Durable Construction: Made with sturdy materials that will last for a long time.

Custom Solutions: Customized to meet the specific needs of each customer.

Safety Conformity: Meets national and international standards.

Local Support: Rapid after-sales assistance throughout West Bengal.

Factors to Consider When Choosing a Single-Phase Transformer

Voltage Requirements: Find the voltages at the output and input levels.

Power Capacity: Pick one that is compatible with the capacity of your load.

Efficiency: Search for transformers that have high-efficiency ratings for energy.

Cooling System: Think about designs that use air or oil that are based on the climate.

Certifications: Make sure the transformer meets the safety and quality standards.

Installation and Maintenance Tips

Correct Location: Place the transformer in a ventilated space.

Secure Mounting: Make sure to secure the installation to avoid vibrations.

Regular Inspection: Look for signs of overheating, unusual noises, and leaks of oil.

Load Monitoring: Don't overload to avoid the possibility of damage.

Professional Service: Schedule regular maintenance by certified technicians.

Conclusion

Understanding what a single-phase Transformer is and what it does in daily electrical systems is essential for providing a reliable and long-lasting power supply. For business and residential customers located in West Bengal, choosing a trustworthy manufacturer such as Makpower Transformers can offer long-term benefits and peace of peace. A high-quality single-phase transformer can help reduce energy losses, safeguard electrical equipment, and guarantee an uninterrupted supply of power.

For more information about our selection of single-phase transformers, contact us today.

English

English