Technical Parameters

Pressure regulating autotransformer

(1) Rated voltage: 6kv, 10kv, 35kv;

(2) Rated capacity: 500kVA to 6000kVA;

(3) Rated frequency: 50Hz;

(4) Number of phases: 3 phases;

(5) Cooling mode: oil immersion self-cooling;

(6) Wiring mode: three-phase three-wire star connection;

(7) Tap level: 7 or 9;

(8) Pressure adjustment range: -10%~~+10%, -5%~~+15%,0~~+20%;

(1) Working power supply: 100~~264V AC/DC;

(2) Rated power: 20W;

(3) Rated frequency: 50Hz;

(4) Analog inputs: 2 channels of 0-220V voltage input, 1 channel of 0-5A current input, and 1 channel of platinum resistance oil temperature input.

(5) Switching quantity: 17 switch input and 6 switch output

(6) Measurement accuracy: 0.5 grade

(7) Anti-interference: Complies with IEC61000-4

Environmental conditions

(1) Altitude: below 2000 meters;

(2) Ambient temperature: the highest temperature is +50℃, the lowest temperature is-35℃;

(3) Pollution level: Grade ⅲ;

(4) Outdoor wind speed not more than 35m/s;

(5) The horizontal acceleration of the earthquake is not greater than 3m/ s2, the vertical acceleration is not greater than 1.5m/ s2, and the safety factor is greater than 1.67.

Diagram

Structural Features

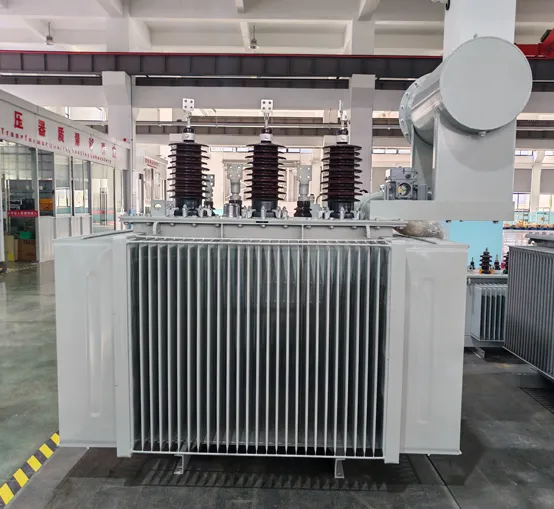

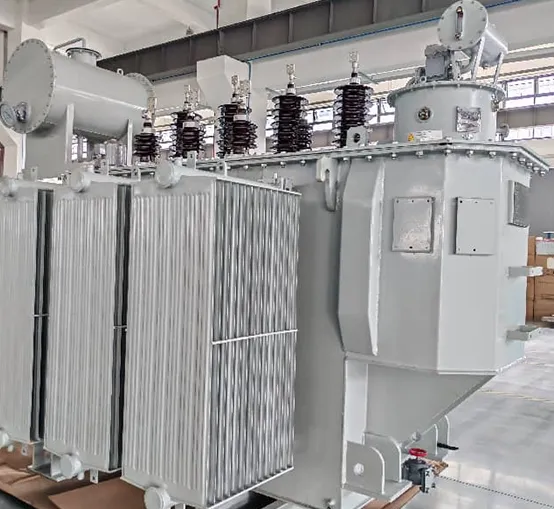

The core is made of high-permeability grain-oriented cold-rolled silicon steel sheets. It is a core-type core with a fully skewed lapped core structure. The core column has a multi-step circular cross-section, and the core yoke and core have the same cross-section.

The windings adopt corrugated oil channels, no varnish impregnation process, and are bound with tight straps. All windings are concentric coils. The corresponding taps of the high and low voltage coils are led to the on-load tap changer, allowing the transformer capacity and voltage to be changed without power interruption.

Transformers with a capacity of 160-630 kVA are equipped with pressure relief valves.

Oil temperature measurement device

All transformers are equipped with a glass thermometer socket, which is located at the top of the oil tank and extends into the oil by 120 ± 10 mm.

The transformer oil tank is made of corrugated walls, with a dust-proof spray coating on the surface and a firm paint film. The corrugated cooling fins not only have a cooling function but also a "breathing" function. The elasticity of the corrugated cooling fins can compensate for the volume changes of the transformer due to temperature fluctuations.

Success Stories

Alateng Mining Co., Ltd. in Inner Mongolia is located at the end of a 10kV power supply line with a total length of approximately 40km, consisting of LGJ-95 and LGJ-70 conductors. The LGJ-95 section spans about 36km, while the LGJ-70 section covers around 3km.

Alateng Mining Co., Ltd.'s primary equipment load includes: 110kW air compressor (1 unit), 132kW air compressor (1 unit), 2132kW hoists, 175kW crusher, 190kW cone crusher, 2210kW ball mills, 290kW blowers, 245kW blowers, and 2132kW slurry pumps. The total transformer capacity is 3470kVA. Prior to installing the SVR line automatic voltage regulator, the equipment could not start normally, with a voltage drop of approximately 3kV during startup. This effectively resolved the voltage issues for Alateng Mining Co., Ltd., earning unanimous praise from users.

English

English