Against the backdrop of an accelerating energy structure transformation, pumped storage power stations, as crucial energy storage facilities, underground pumped storage projects, favored for their small land footprint and high safety, have emerged as a construction hotspot in recent years. However, the unique environment of long-term high humidity and limited ventilation in underground spaces poses extremely strict requirements on the weather resistance and stability of core electrical equipment. In a large-scale underground pumped storage project, Tenrony’s YB-12/0.4kV-1000kVA prefabricated substation and ZGS-12/0.4kV-500kVA assembled transformer(American-style transformer) have successfully completed the power supply guarantee task with their outstanding adaptability and reliability, setting a benchmark for the application of electrical equipment in humid environment.

Project Background: The Power Supply Challenge in Humid Environments Awaits a Solution

This underground pumped storage project is located in a southern region of China with abundant rainfall. The underground power plant and its supporting facilities are over 100meters deep, and the internal relative humidity remains above 85% throughout the year. In some areas, due to the risk of groundwater seepage, the short-term humidity can even approach saturation. As the”heart” of the project’s power system, the transformer not only needs to handle the power supply tasks for core operations such as unit startup humidity on the insulation performance of equipment and corrosion of metal components.

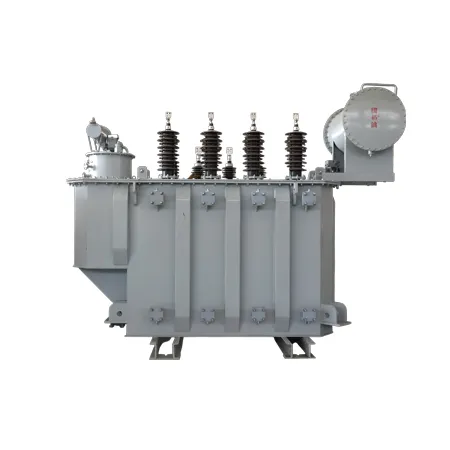

During the early research and investigation stage of the project, several traditional transformer brands were excluded because they could not meet the strict requirement of “continuous stable operation in a high-humidity environment for a long time, with an average annual downtime of no more than 2hours.” After extensive investigation and rigorous testing, Tenrony Electric’s YB-12/0.4kV-1000kVA prefabricated substation and ZGS-12/0.4kV-500kVA assembled transformer(American-style transformer)were successfully selected for the core power supply equipment list due to their specialized optimization design for harsh environments.

Product Adaption: Customized Design Addresses Environmental Challenges

In response to the core challenge of the underground damp environment of the project, Tenrony Electric has carried out multiple specialized optimizations in the design and production stages of two products, fundamentally enhancing the environmental adaptability of the equipment:

YB-12/0.4kV-1000kVA Pre-assembled Substation: Integrated Protection Strengthens Safety Defense

As the main power supply unit of the project, this pre-assembled substation adopts a fully sealed box structure design. The box is made of 304 stainless steel and undergoes multiple anti-corrosion spray treatments, effectively resisting metal corrosion in damp environments. Inside the box, and intelligent dehumidification system and real-time temperature and humidity monitoring module are equipped. When the humidity exceeds the set threshold, the system sutomatically activates the dehumidification device, stabilizing the box’s humidity within the safe range of 50%-60%,ensuring the insulation performance of the equipment from the perspective of environmental control.

In terms of core component selection, the transformer core uses high-permeability silicon steel sheets, and the windings are made of insulation materials with a moisture and heat resistance rating of H-class, which undergo vacuum drying and varnishing treatment, further enhancing the moisture resistance of the insulation layer. Additionally, the equipment integrates a comprehensive fault warning system that can monitor key parameters such as insulation resistance and winding temperature in real time. Once an anomaly is detected, it immediately issues a warning signal, providing maintenance personal with time to handle the situation.

ZGS-12/0.4kV-500kVA Assembled Transformer(American-style Transformer): Modular Structure for Complex Installation Scenarios

In response to the limited installation space and inconvenient transportation for underground projects, this assembled transformer adopts a modular design. Its components can be disassembled for transportation to the underground site and then quickly assembled, significantly reducing the construction difficulty. The product’s interior features a fully insulated and sealed structure. Both the high-voltage and low voltage windings are enclosed in specially designed moisture-resistant insulating tubes, and are combined with dedicated sealing gaskets and pressure balancing devices to effectively prevent moisture form entering the equipment.

Furthermore, this transformer has optimized its heat dissipation structure, using a combination of natural cooling and forced ventilation. Even in underground environments with limited a safe range during full load operation. Its casing is also treated with anti-corrosion and anti-rust measures, and coated with a special layer that is resistant to moisture and wear. After 1000 hours of salt spray testing, there was no obvious rust, fully meeting the project’s requirements for a humid environment.

Project Performance: Stable Operation Builds a Reliable Reputation

Since the official operation of the project, the Tenrony YB-12/0.4kV-1000kVA pre-assembled substation and the ZGS-12/0.4kV-500kVA assembled transformer have been operating stably for 18 consecutive months. During this period, they have withstood multiple harsh environmental tests such as the rainy season and fluctuation in groundwater levels, the operating parameters of the equipment have remained within the normal range, the insulation resistance values have been stable, and there have been no shutdowns due to damp conditions. According to the project’s operation and maintenance data, the average load rate of the two transformers is 82%, and the power supply reliability is 99.98%, far exceeding the project’s expected requirements. Their outstanding performance not only ensures the efficient operation of the pumped storage units but also significantly reduces operation and maintenance costs-due to the high stability of the equipment, maintenance personnel only need to conduct regular inspections quarterly, reducing the annual average operation and maintenance costs by approximately 30% compared to similar projects.

Case Summary: Precise Adaptation Leads to Industry Benchmark

The successful implementation of this underground pumped storage project has fully demonstrated the outstanding performance of Tenrony’sYB-12/0.4kV-1000kVA prefabricated substation and ZGS-12/0.4kV-500kVA assembled transformer in damp and harsh environments. Through in-depth research on project requirements, Tenrony Electric has carried out targeted product optimization designs, employing core technologies such as fully sealed protection, intelligent environmental control, and moisture-resistant insulating materials to solve the operational challenges of transformers in underground high-humidity conditions.

This case not only provides valuable experience for the selection of electrical equipment in the pumped storage industry under adverse conditions but also highlights Tenrony Electric’s technical strength and innovation capabilities in the field of power equipment research and production. In the future, Tenrony Electric will continue to focus on the equipment needs of special scenarios such as new energy storage and underground engineering, constantly upgrading its products to provide reliable solutions for power supply in more demanding environments.

English

English