Recently, the 800-kilovolt 80-kilowatt circuit breaker developed by Pinggao Electric, a member of the China Electricity Council, in collaboration with State Grid Shaanxi Electric Power, Xi'an Jiaotong University, and China Electric Power Research Institute, has passed all type tests and verifications. This marks the successful development of the world's first 800-kilovolt 80-kilowatt circuit breaker, promoting the progress of high-capacity high-voltage switch technology in China. It provides a solution for the capacity expansion of China's 750-kilovolt power grid and is of milestone significance for ensuring the safe and stable operation of China's power grid and enhancing power transmission capacity.

With the rapid development of large-scale new energy access and cross-regional DC transmission, the capacity of the 750-kilovolt power grid in Northwest China has been continuously increasing, and the short-circuit current level has also significantly risen. This has become a prominent factor restricting the growth of power grid load and long-term development in China, posing challenges to the continuous advancement of the green and low-carbon transformation of energy. Therefore, based on the large number of operational equipment in the Northwest power grid, State Grid Shaanxi Electric Power Company proposed the requirement that 80-kilohm circuit breakers and 63-kilohm circuit breakers be interchangeable. Relying on the research and development foundation of Pinggao Electric's 550-kilovolt 80-kilohm circuit breaker, the project team jointly initiated the research and development of the world's first 800-kilovolt 80-kilohm circuit breaker.

Under the premise of maintaining the interface size of the 63 kA circuit breaker unchanged, the development of the 800 kV 80 kA circuit breaker faces many technical challenges. The short-circuit current energy increases by 60%, the recovery voltage rise rate of the key test increases by 27%, the breaking difficulty significantly increases, the ablation resistance performance of the core components needs to be further improved, and the mechanical performance of the product also faces higher requirements. The existing products and technologies cannot meet the requirements. For this reason, the project team worked together to solve the problems and focused on breaking through the following key technologies.

Overcome technical difficulties:

1. The core technology for breaking 800-kilovolt and 80-kilowatt large-capacity circuits has been conquered. The project team delved deeply into arc theory, innovatively established an 80-kilowatt high-precision arc model in the switch field, set up an internationally advanced arc measurement system, mastered the arc characteristics under high-voltage and high-current conditions, and successfully developed the world's first 800-kilovolt and 80-kilowatt double-break arc extinguishing chamber.

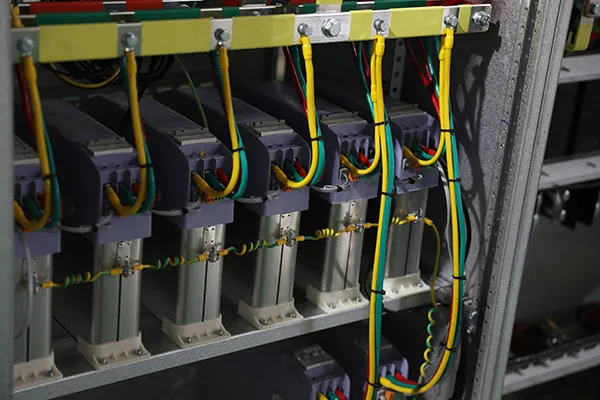

2. The project team focused on enhancing the arc erosion resistance of key components to withstand 80 kA arc erosion. They concentrated on improving the erosion resistance of the nozzle and copper-tungsten contacts, studied the optimal particle size ratio of the matrix and filler, optimized the forming process, and combined with the technological innovation of graphene contacts to meet the 20 times electrical life requirement of 800 kV 80 kA circuit breakers, solving the problem of burn damage under extreme working conditions.

3. Breakthrough in the collaborative optimization technology of large-capacity breaking and operating characteristics. In response to the breaking performance requirements of 80-kilovolt-ampere circuit breakers, research on the mechanical characteristic matching of the operating mechanism and the optimization of the buffer structure is carried out. The collaborative optimization technology of large-capacity breaking and operating characteristics is broken through. Foreign matter control of moving parts is strengthened, and the transmission system is optimized to ensure the mechanical and electrical reliability.

Product performance features:

1.The technical parameters are internationally leading and the performance indicators are outstanding. The overall performance of the product reaches the E2-M2-C2 level, all meeting the highest parameters stipulated by the standards. Among them, the electrical life is 20 times, the mechanical life is 10,000 times, and the DC component time constant is 120 milliseconds.

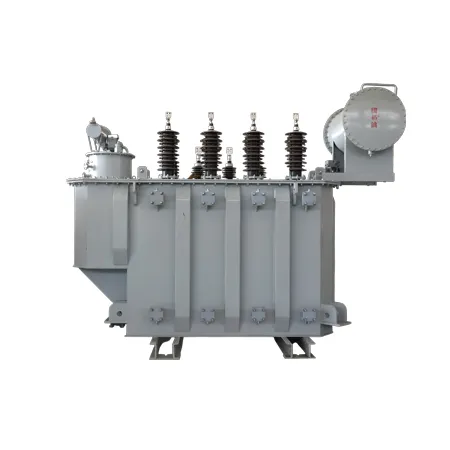

2.The structure is mature and reliable, and the insulation and mechanical performance are stable. The product is developed based on the mature 800-kilovolt 63-kilowatt circuit breaker technology, adopting the double-break gas-pressure arc extinguishing chamber and hydraulic operating mechanism. Meanwhile, through foreign matter process control and transmission system optimization and improvement, the insulation and mechanical reliability of the product have been further enhanced.

3.It features strong interchangeability and is convenient and efficient for engineering applications. The interface size of this product is exactly the same as that of the existing 63-kilovolt products in operation, which enables in-situ capacity expansion and replacement transformation of the existing equipment in the substation without changing the engineering layout and foundation structure. It has outstanding advantages such as short construction period, minimal power outage impact, and excellent economic performance.

Source: Pinggao Electric

Editor: Luna.Li

English

English